Working principle

The fully rotary drilling rig includes a power station and a working device, and the power of the working device comes from the power station.

Common construction methods for fully rotary drilling rig

Construction method of cast-in-place pile in complex strata and special environments

Construction method of drilled bite pile

Construction method for removing piles and underground obstacles

High precision and unbiased steel column insertion construction method

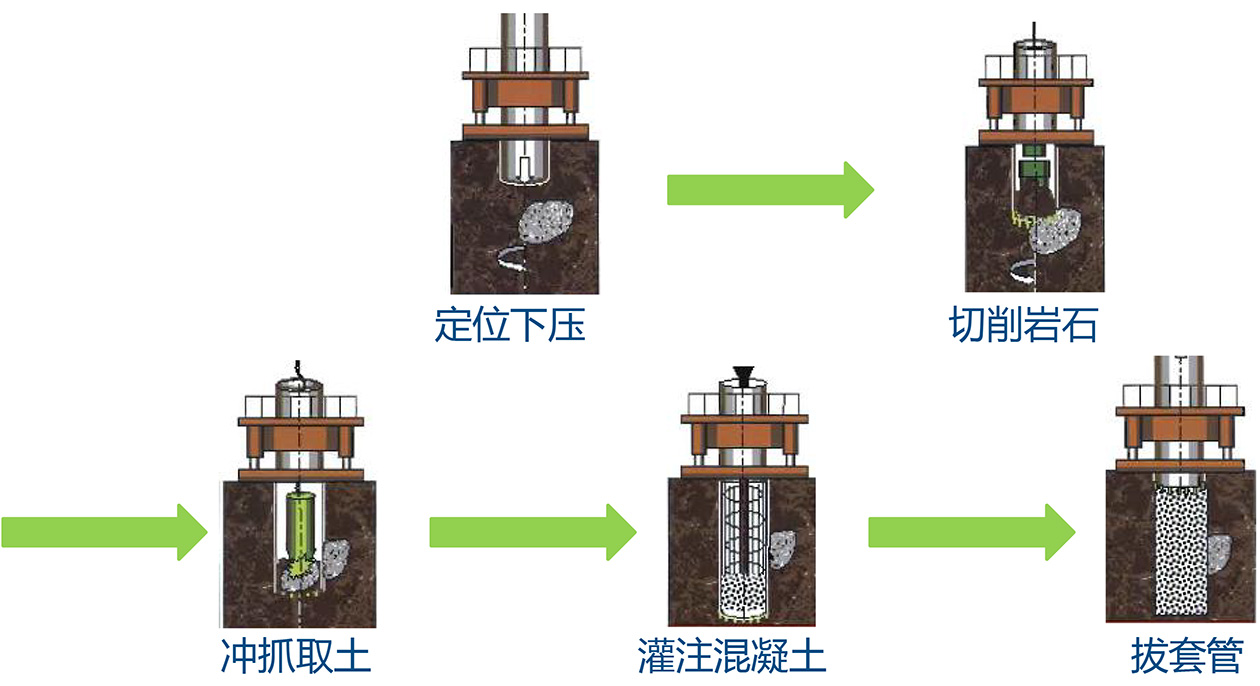

Rotary drilling rig+casing process flow

Measurement and laying out → Equipment positioning → Embedding casing → Rubbing casing → Grab bucket digging soil → Lifting steel cage → Pouring concrete → Pulling casing → Equipment positioning next pile

1. Set the pile position of the fully rotary drilling rig.

2. First, connect the 8-meter pipe boots and then install them onto the fully rotating drilling rig. The sleeve is connected to the boot with screws, making it easy to disassemble and assemble.

3. After setting the pile position, use a fully rotary drilling rig to drive the casing for drilling construction. After drilling into one casing, the other casing can be lifted by a crane and connected to the casing that has been drilled underground, and then drilling construction can continue.

4. During the process of driving casing drilling, if there are difficulties in drilling the casing, it is necessary to use an impact hammer, impact grab or rotary drill bit to enter the middle of the casing and take soil.

5. Unload the soil.

6. Drive the casing drilling method until the designed depth is reached, and the drilling work is completed.

7. Lower the steel cage and pour concrete. Place the steel cage in the middle of the casing, and then insert the grouting conduit. At this point, concrete pouring begins. The entire pile hole should be poured with concrete for as short as possible. If the pouring time is too long, it will cause difficulty in pulling out the casing after the concrete solidifies, leading to construction accidents. During the process of pouring concrete, the casing can be pulled up a certain height to prevent it from sticking after the concrete solidifies.

Matters needing attention

1. The casing should avoid strong collisions, especially at the joint of the casing. When loading and unloading the casing connection pin, it must be cleaned thoroughly, otherwise it will cause installation difficulties.

2. When the torque increases to the point where driving the casing becomes difficult, it is necessary to use an impact grab or rotary drill to advance the drilling.

3. Before lifting the rotary drilling bucket, the alignment and perpendicularity of the drill pipe hole should be checked to prevent the opening and closing mechanism from hitting the casing shoe during lifting, and to open the bottom door under the hole.

4. When pouring concrete, it is necessary to test whether the various actions of the pipe pulling machine are normal before starting to pour concrete.

5. After the grouting is completed, immediately pull out the casing to prevent the cage from floating.

Introduction to drilling rig

♦ The full casing and full rotary drilling rig is a new type of drilling rig that integrates full hydraulic power and transmission, electromechanical hydraulic joint control, and can drive the casing to rotate 360 degrees. It can simultaneously press in the casing and drill, and can solve the problem of pile foundation construction in complex and special environments.

Drilling rig principle

The full casing and full rotary drilling rig belongs to a type of Benoit drilling rig. The specific construction principle is:

By utilizing the rotation of the full casing and full rotation drilling rig, the frictional resistance between the steel casing and the soil layer is greatly reduced. The steel casing is pressed in while rotating, and the soil is excavated or rotated using a grab bucket or impact hammer until the casing reaches the bearing layer at the pile end. After excavation is completed, immediately measure the depth of the hole to confirm the bearing layer. After meeting the requirements, clean the hole, install the steel cage, and pour concrete to form the pile.

Technical principles

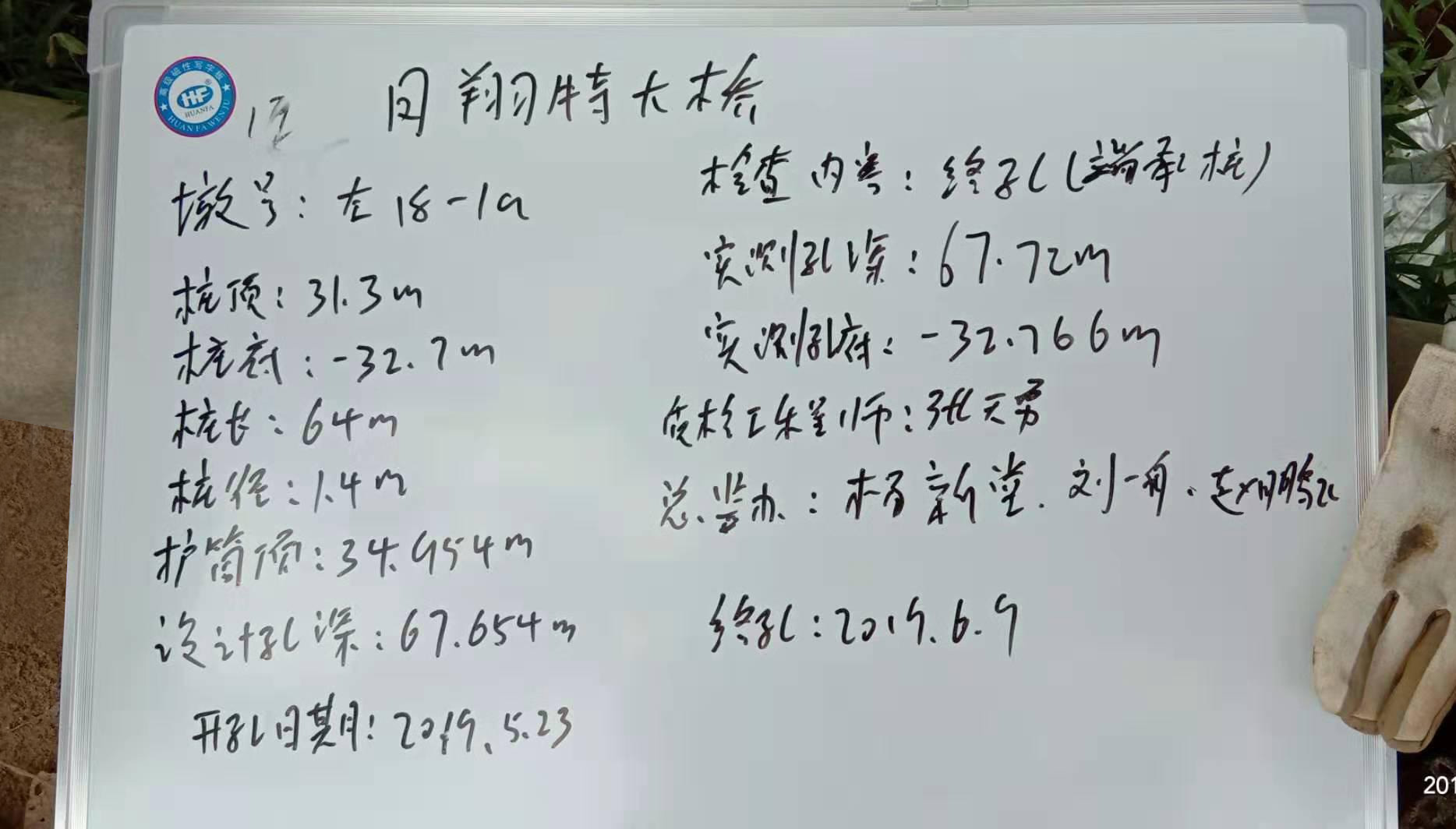

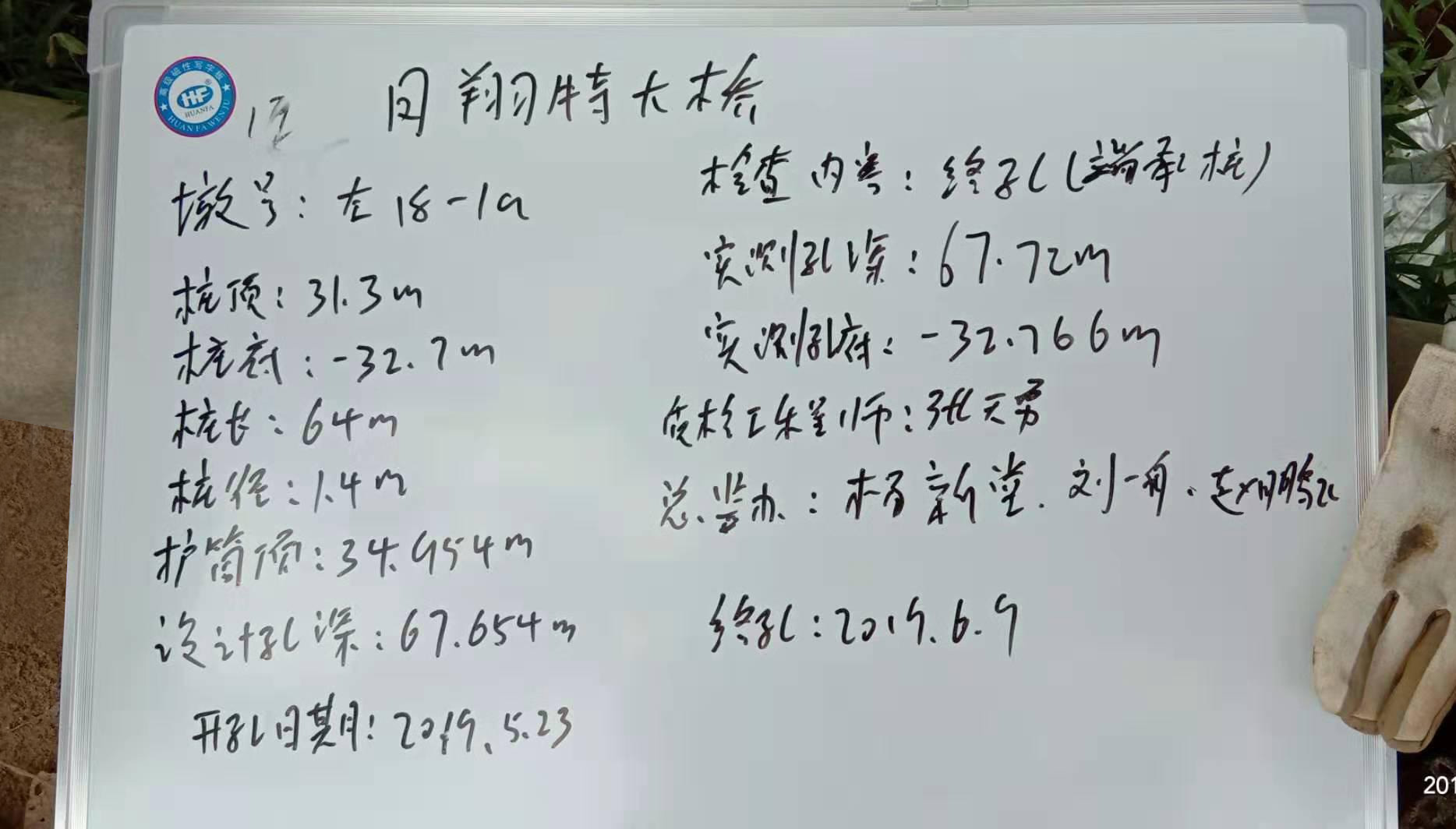

Typical bar chart

Main construction measures

♦ Adopting disposable casing technology to solve the problem of concrete leakage in karst caves;

♦ Using specially designed blade heads, blade holders, and blade barrels to solve the problem of ultra deep rock penetration;

♦ After entering the limestone, a soil extraction process combining impact and grabbing is used;

♦ The bottom sediment of the pile is treated with gas lift reverse circulation technology to achieve zero sediment at the bottom of the pile;

♦ The outer diameter of the steel cage used for production should be 10cm smaller than the inner diameter of the casing. At the same time, a circular precast concrete protective block should be installed every 4m on the steel cage to ensure that it is in the center of the casing and not hung out by the cutting head or lifted by the conduit.

Technological process

Construction operation

Use block stones to backfill and harden

the upper 3m range of the original

subsidence area after compaction |

Drilling rig in place

|

Drilling and soil grabbing

|

Sleeve docking |

Verify verticality |

Sleeve cooling protection (immersion) |

Hole depth

acceptance |

Mechanical hole

cleaning once |

Docking and placement

of steel cage |

|

Placement of catheter |

Secondary cleaning of holes |

Pouring concrete |