Step 1: select forging the original embryo. (Selected 25CrMo round steel) |

Step 2: rough forging, rapid heating, rough forging with hydraulic hammer to make rough. Do high-frequency quenching and tempering process. |

|

|

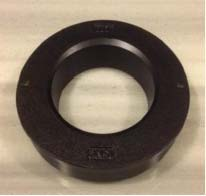

Step 4: Put on the vertical CNC lathe and turn to the required size. |

Step 5: On the horizontal CNC boring machine, accurately position and boring the connecting holes and positioning pin holes. |

|

|

|