Casing

Construction of casing

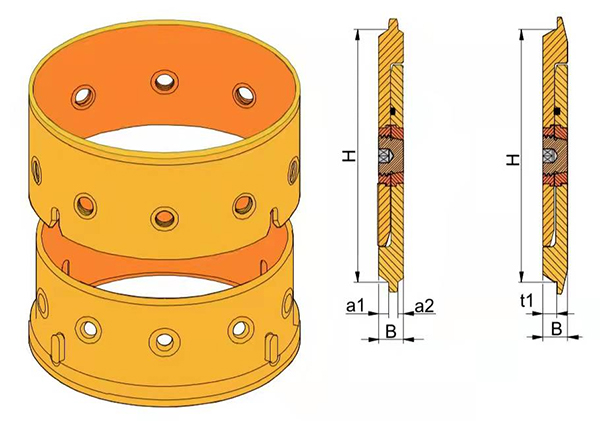

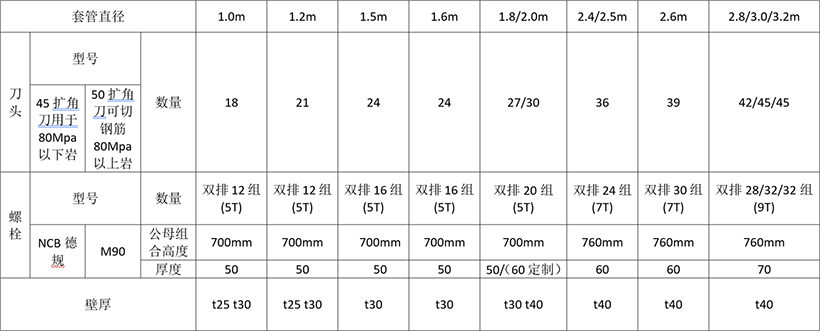

1) Double layer board sleeve

The middle of the male and female joint of the double-layer plate sleeve is a double-layer structure composed of an outer plate and an inner plate. Insert another layer of padding between the outer and inner panels. The thickness of the joint part (T) is almost the same as the thickness of the outer plate+cushion plate+inner plate (t1+t2+t3=t4). The characteristics of double-layer casing are good rigidity, low deformation and good recovery, sturdy and durable, but the disadvantage is heavy weight and high cost.

2) Single layer casing

The middle of the male and female joint is a whole board, and there are steps between the tube body and the male and female joint. The characteristic of single-layer casing is that it is lighter in weight and cheaper in price, but it is prone to deformation and difficult to recover after deformation.

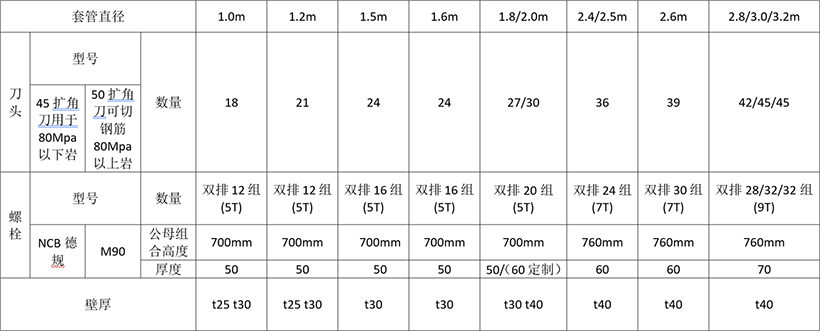

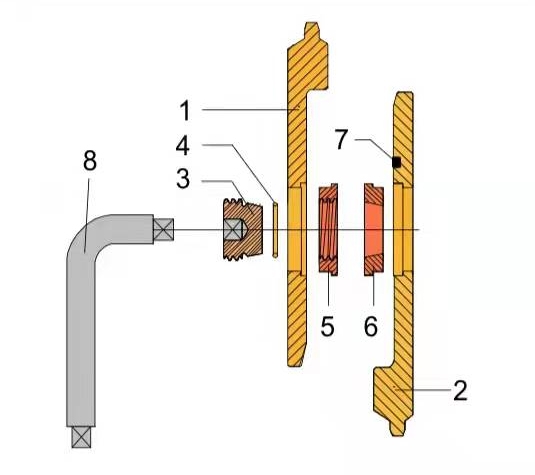

3) Type of casing and plate thickness

At present, there are many casing manufacturers used in the market for fully rotating full casing drilling machines, and the dimensions of casing joints, wall thickness, etc. are often inconsistent. The commonly used ones are shown in the table below.

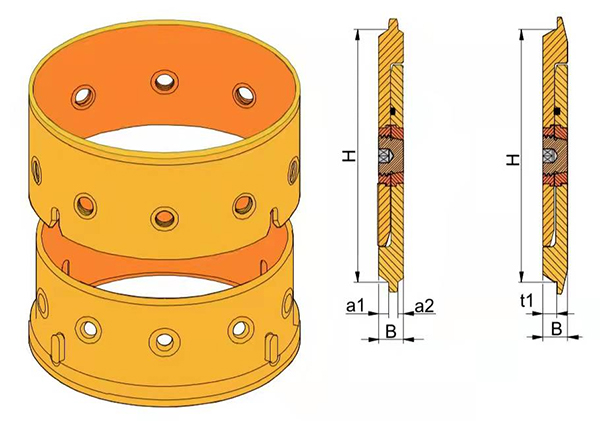

Connection of casing

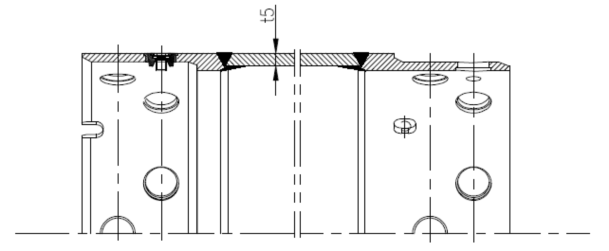

The connection of the male and female joints of the casing is fastened using bolts. The complete set of fastening bolts consists of three parts: male wedge head, female wedge head seat, and female wedge head. They are fastened with conical surfaces and are not easily loosened. It should be noted that if foreign objects such as soil and sand are mixed into the cone surface, it may cause deformation of the cone surface, welding fracture, insufficient tightening, and inability to loosen during disassembly. It must be cleaned before use.

|

|

Use of casing

1) The length of the casing includes various types such as 2, 3, 4, 5, and 6 meters. 6 meter long casing is commonly used, and the number of casings of each length is prepared according to the needs during construction. The length of the bottom section casing with bottom casing can be appropriately extended.

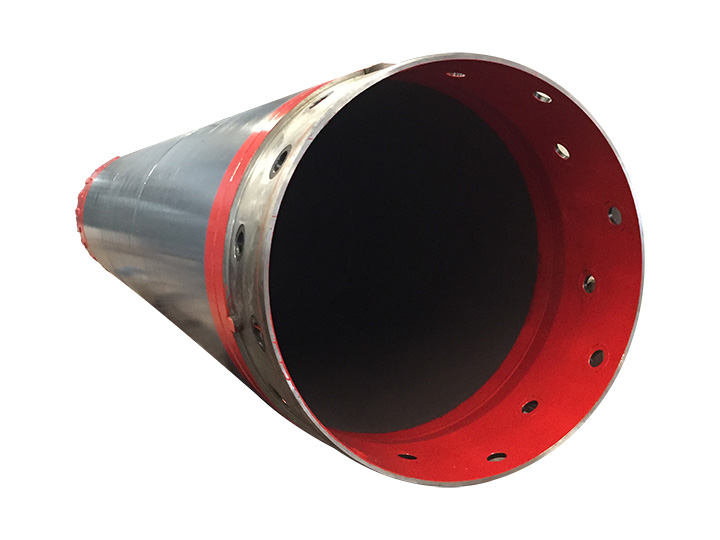

2) The bottom sleeve (the sleeve at the bottom of the blade) is usually a single-layer tube made of thick plates. The length is usually around 8m.

3) The casing connected to the bottom casing is susceptible to hammer impact or heavy hammer impact, resulting in deformation of the inner plate and frequent replacement of position with other casings.

4) The joint above bears the load in the joint section.

5) If there is deformation or damage to the joint, it should be replaced in a timely manner. If it needs to be reused, it should be connected to the lower part because the lower part has a relatively small acceptance, is not easy to loosen, and is easy to ensure safety.

6) Even if the shape and diameter of the casing, casing joint, and joint bolt are the same, the machining dimensions of the casing and casing joint parts from different manufacturers may also be different. Therefore, when using them, it is necessary to consider the non universality of products from different manufacturers.